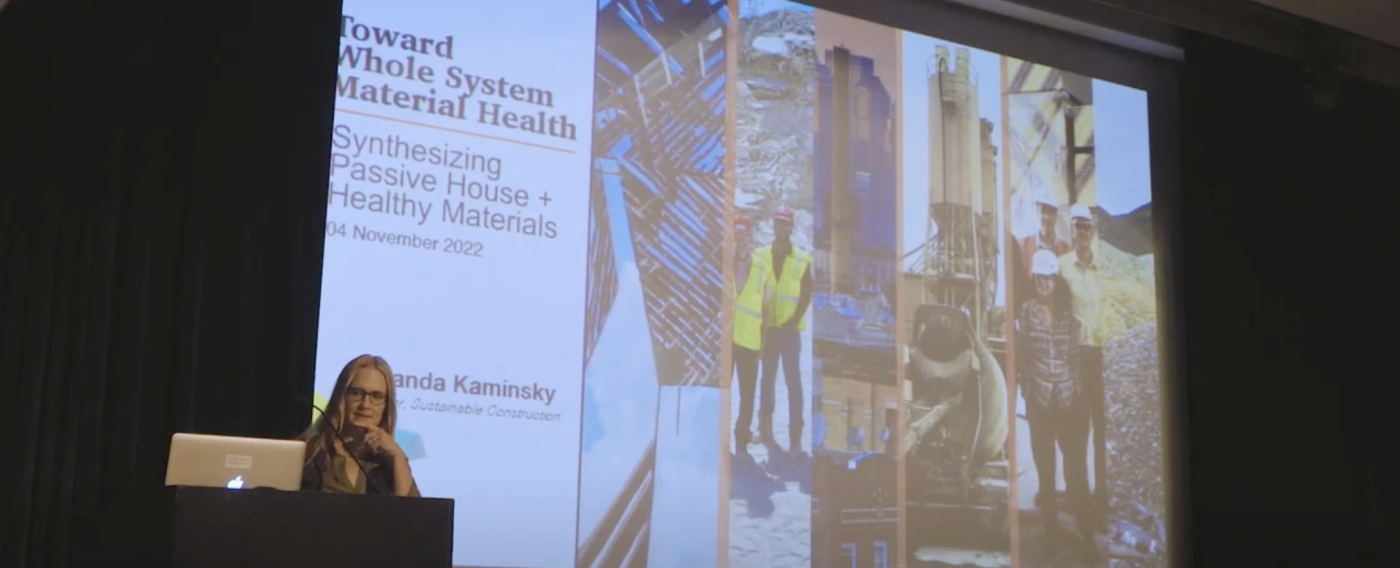

Alum in Action: Amanda Kaminsky on the importance of circular construction

Amanda Kaminsky (BSArch '99), LEED® AP, CPHT

Director of Sustainable Construction, Lendlease

Alumna Amanda Kaminsky (BSArch '99) recently spoke at the New York Build 2025 Expo as part of a session titled "From Waste to Wealth: Circular Construction for a Sustainable Future." Drawing upon several decades of experience in leading collaborations with multidisciplinary teams resulting in lasting industry improvements, we asked Kaminsky, who is Director of Sustainable Construction for Lendlease's Americas portfolio, to share more about her efforts in bringing sustainable solutions to the making of architecture.

Why is circular construction critical to sustainable building solutions?

In New York, where I live and do much of my work, buildings are responsible for about 70% of the city's total emissions. Of the total greenhouse gas emissions attributed to the building sector globally, the World Green Building Council estimates that embodied carbon of construction materials accounts for over a quarter.

We know that implementing circularity via reuse of building materials creates a system in which the production and purchase of new materials is avoided, therefore eliminating a large segment of embodied carbon impact.

Seeing our construction projects as ecosystems

where no resource is wasted, and then using smart

logistics to figure out implementation with our

supply chain and recycling partners enables us to

make circularity happen on the ground.

Circular resourcing is also making our supply chains more local, and therefore more resilient.

Prior to your role at Lendlease, you established and led Building Product Ecosystem LLC (BPE), a public private partnership that piloted improvements to product, process, standards, and infrastructure across many stakeholders, from building owners and design/construction teams, to suppliers and policymakers.

Tell us about what led you to founding BPE.

At The Durst Organization, I was working with our teams to optimize the systemic health of some of our higher volume building materials ubiquitous across our projects and the industry, like concrete and drywall.

We realized quickly that many others were interested in realizing these same improvements, and that we needed collaboration with these folks in order to drive the scaled change sought. Durst and I first established Building Product Ecosystems/BPE as a public private partnership in 2014 with local institutions, City University of New York, and Parsons The New School, as well as Healthy Building Network and Vidaris.

We held monthly collaborative meetings bringing the necessary researchers, manufacturers, recyclers, government entities, designers, and building owners together to strategize action and pilots for improvement. As interest continued to grow in BPE, I founded it as an independent LLC in 2015 to take it on full-time.

BPE has helped to normalize source separation and remanufacturing of gypsum drywall trim scraps back into new drywall, reducing gypsum mining and preventing drywall from being landfilled where it is a primary cause of hydrogen sulfide gas formation -an asthmagen affecting landfill-adjacent communities.

BPE also collaborated to establish ground-glass pozzolan as a local, recycled, non-toxic, low-embodied carbon cement replacement.

Ground-glass pozzolan makes concrete that is lighter in color, or lower albedo, importantly reducing urban heat island effect in the paving throughout our cities. It also creates a less permeable concrete, resulting in greater durability in chloride environments and where concrete goes through freeze-thaw cycles.

You also collaborated with New York City Dept. of Sanitation to execute the city’s first highrise residential organics collection/compost program — what were the goals, some challenges, and some successes in realizing this program?

The goals of that initial high rise residential organics collection pilot were to demonstrate that organics collection could work in dense, urban environments, and to vet the education of building staff and tenants and the collection implementation via an initial pilot before making any necessary adjustments and scaling.

There is so much individual and collective benefit

to direct engagement with turning your own

food scraps into nutrient-rich soil that nourishes

ensuing cycles of local growth.

The biggest challenges were evolving entrenched habits and keeping infrastructure clean without introducing additional layers of plastic bags into the system.

The building staff and tenants were very engaged and wanted to be informed. They visited sites where the actual compost processing was happening around the city, and provided useful feedback for improvements that have informed how collection is happening today.

Following, we proceeded to roll the program out across our portfolio.

If you take a moment to look back, what do you continue to take with you into your professional life from your time as a student at the A-School?

I had the pleasure of studying under deeply insightful

professors that consistently urged me to see the

whole system of social and environmental impacts

and opportunities inherent in each and every

design decision we make.

I also developed and carry with me an incredible network of friends and colleagues through my A-School classmates that I have continued to grow with and from over the years. We are all doing different and interesting work, and benefit from deep bonds forged in studio in the late 90s!